New range of SCM machining centres for solid wood

SCM is changing the ‘rules of the game’ for machining doors, windows, stairs and solid wood elements. At the heart of the new accord 500 and accord 600 models and the upgrade of the morbidelli m200 lies the need for customers to regain control over their time, making significant gains in productivity while still achieving excellent quality on finishing.

According to wood: behind the claim chosen by SCM for the launch of its new range of machining centres for solid wood, lies the meaning and value of a project called upon to launch a new era in machining doors, windows, stairs and much more.

According to wood describes SCM's desire to provide a vast range of technical solutions that are even more effective and better performing, but above all “designed by wood” because they have technical specifications and performances that are fully in line with market challenges.

At the same time, According also brings to mind accord: a long history of successes and know-how like that of SCM's range of machining centres for drilling and routing, of the same name, and which has been a benchmark for the industry for over 15 years.The same range is now being expanded and renewed from a completely new and strategic point of view, to stay abreast of the times and to rightly value customers’ time, by optimising and speeding up production processes, while simultaneously guaranteeing excellent finishing quality.

In fact, it has been time that has mostly led the revolution of SCM machining centres. Each technical feature is designed to save time at the most crucial stages for each industry manufacturer: from machine programming to set-up, from the machining process to maintenance. “Our aim was to give our customers, facing increasingly more complex problems when machining solid wood, an answer from specialists capable of finding precise solutions for each individual request. These new technologies considerably simplify the everyday work of operators, making it more efficient and, as a result, ensuring an even greater return on investment”, underlines SCM's Business Manager for Machining centres, Bruno Di Napoli.

New Acoord 500/600 machining centres

SCM increases productivity by 30% compared to market standards thanks to the “gantry” structure with closed frame that, in continuity with the accord project, allows for sturdiness and precision to be achieved even at maximum advancement speed and with the most difficult machining jobs.

The routing speed is further increased and now exceeds 15 metres per minute with the new 5-axis KPX machining unit with Hiteco 17 kW electro-spindle, designed to always allow the most complex operations to be carried out rapidly and accurately.

Even the production cycle times are dramatically reduced with the exclusive BRC-S unit, that is even more flexible and compact and allows you to complete all the cutting, routing and drilling machinings typical of window components.

Another significant new entry is the more than 100 tools readily available and easily ready for use with the new Caddy 35 storage, unique both for its capacity as well as its structure because it is integrated into the machining centre without increasing the machine's bulk.

Tool management is further optimised and simplified by the new Maestro Power TMS software, integrated with SCM's Maestro suite. Thanks to this program that maximises the ability of the storage and optimises programming, there is no need for the operator to waste time and energy in looking for the most suitable tool: the software will identify and indicate the tool's exact position in the storage thus minimising machining times.

Cleaning the surrounding area is another crucial matter when machining solid wood and, in order to deal with the problem, SCM has devised a new shavings conveyor automatically positioned in accordance with the machining program, that can ensure maximum suction efficiency under any condition.

A range, greater demand

The According to Wood project is offered to the market with a range that fully satisfies the various production needs.

Accord 500 combines tradition, simplicity and compactness, without sacrificing high technology: Ultimate power, for wood applications, developed by the new 5-axis machining unit with 17 kW electro-spindle and the possibility of choosing a Pro-Space configuration without perimeter protection, that is ideal for those who do not have a great deal of space available.

Accord 600 is the project solution that involves no compromising on performance: with a view to reducing production times as much as possible in any application field, it offers a completely new, hyper-performing machining unit fitted with as many as 3 separate units.

The 4-axis and JQX 5-axis electro-spindles, respectively from 21 to 13.5 kW with separate on-board storages, allow for tool change while the machine is running and even during machining of the separate front unit, with BSC-S or head to drill, as required.

All aimed at saving time, which is the absolute key concept throughout the entire range.

The upgrade of the Morbidelli m200 ‘all-in-one technology’ machining centre

The morbidelli m200 range, benchmark for CNC machining centres across the globe, confirms its technical features as the most popular on the market, like its solid structure, its 250 mm component passage, its Prisma KT 5-axis and the FlexMatic table that ensures that not only all kinds of machining for panels can be achieved by also those for solid wood.

This machining centre has now been enhanced with new features that are ideal especially for the production of window elements.

Cycle time reduction with the FlexMatic table that becomes even more flexible with its movements that are made simultaneously under the control of SCM's Maestro CNC software.

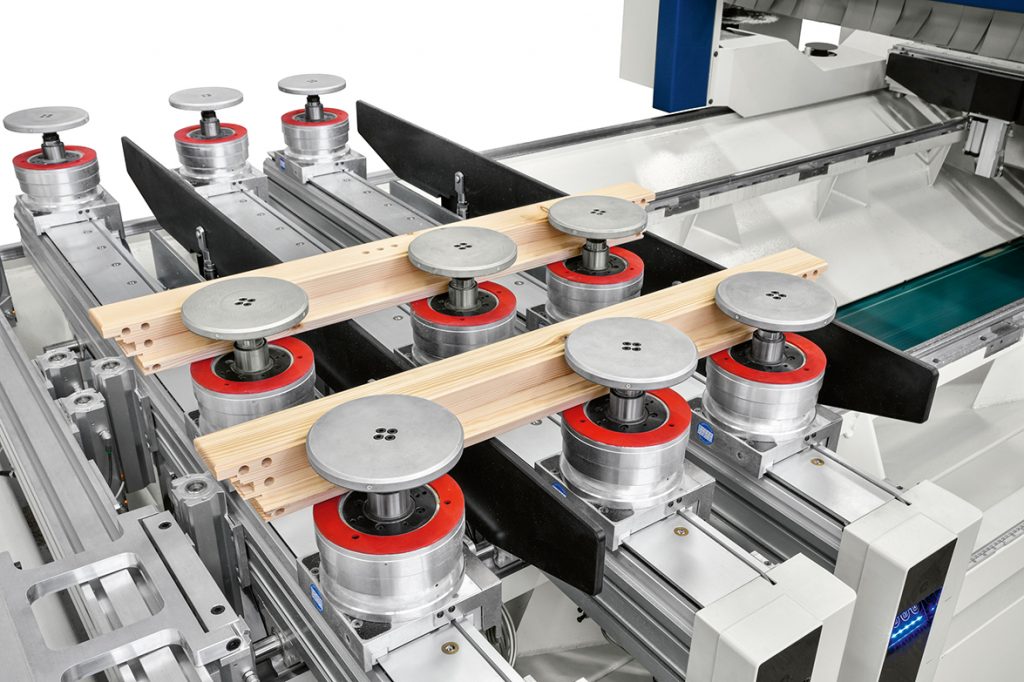

As well as this, the performance of the piece-gripping system has been further enhanced thanks to the MULTIGRIP clamp, designed to specifically machine elements for windows and doors, that allow the work pieces to be positioned and blocked faster and more reliably.

Important new entries for the JQX machining unit that is enhanced by an innovative shavings conveyor specifically designed to achieve maximum cleaning even in the presence of significant removals. This is controlled by NC not only in rotation, following the machining direction, but also in vertical position: this means the conveyor can always position itself directly in front of the jet of shavings to capture it as effectively as possible.

Confirming the focus on the world of windows and doors, even on the morbidelli m200, we find the new BRC-S unit that allows for horizontal blade cuts and drilling and routing to be achieved as quickly as possible, leaving the 5-axis spindle with just the main profiling and tenoning operations to do.

News Infurma:

Online Magazine of the International Habitat Portal. Design, Contract, Interior Design, Furniture, Lighting and Decoration